The Reloading Bench

Pan Lubing Explained

other By: Steve Garbe | December, 25

For some reason, one of the hardest things to explain over the phone is the concept of pan-lubing. We get many calls from folks new to black powder shooting who hear of “pan-lubing” and don’t comprehend the procedure, or can’t understand why it is necessary to use on particular designs of bullets. Hopefully in this installment of the Reloading Bench we can explain pan-lubing and why it is necessary in some instances.

When one wishes to use a tapered bullet design, pan lubing is the best way to apply lubricant. You can run tapered bullets through a lubri-sizer, but unless the sizing die is the same size as the largest driving band on the bullet you will simply turn a tapered bullet into a parallel-sided bullet. Using a sizing die that is as large as the largest band will work, but is very messy and a waste of lubricant. Pan lubing insures that the bullet diameter is not altered and that lube grooves are filled with solid lubricant.

First, let’s make the double boiler. The simplest arrangement is using a pie tin for the bullet tray and a slightly deeper, heavier tray for the water tin. It is a easy task to find two tins at the local “Walmart” that will fit one inside the other. However, a coffee can may be used for the “water-tin” and in many ways I prefer it as it will hold a greater supply of water. This lessens the risk of running the water-tin dry and scorching the lubricant. The only other item needed is a one-burner hotplate with an adjustable heat setting. It is important that the bullet tin have tapered sides that allow the easy removal of the bullet “pie” when the melted lube solidifies.

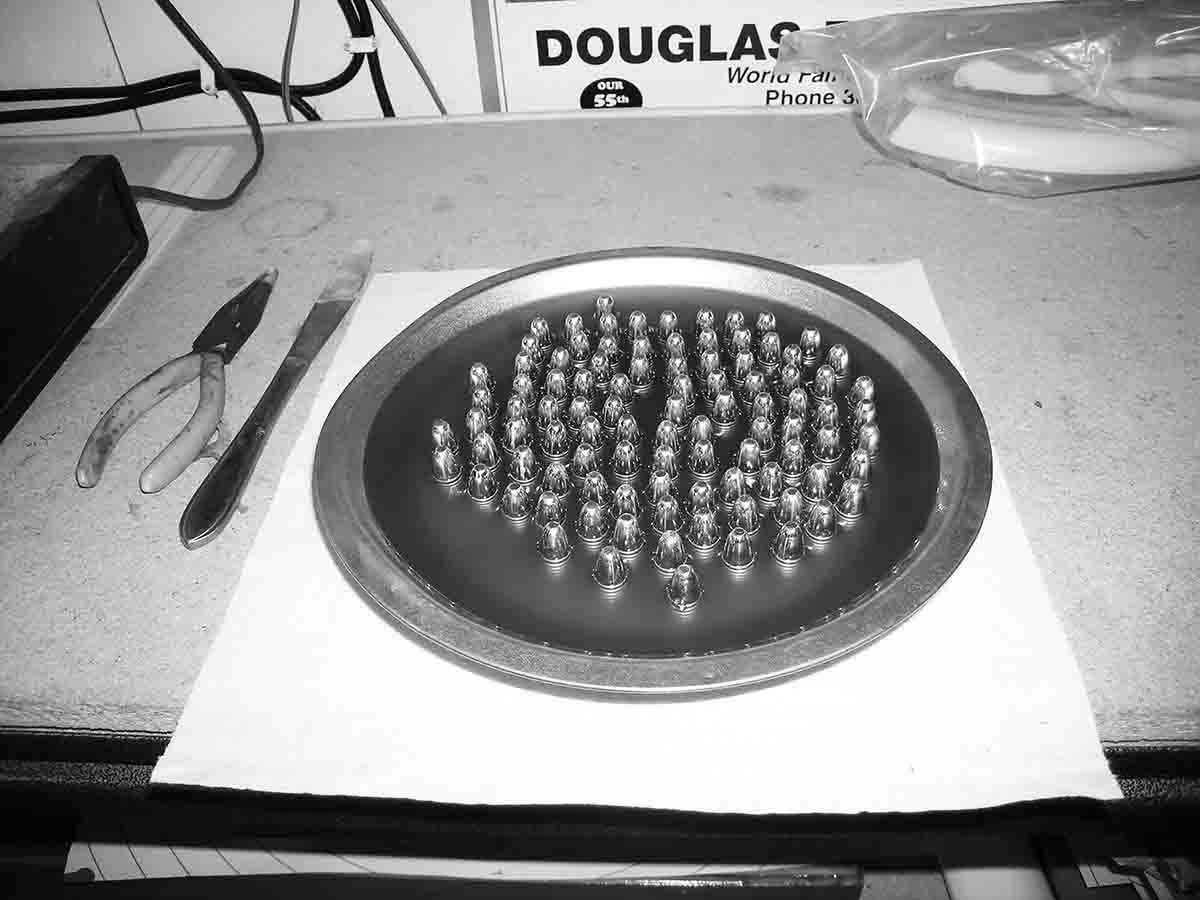

If you are setting up for the first time, simply add a quantity of bullet lube in the top pan and let it melt. Once it is melted, stand the bullets up, base first, in the melted lubricant. Be aware that the bullets will displace the lube and cause the level to rise in the pan. Also be careful that hot lube does not spill on to the hotplate as this could be a fire hazard. You may have to use wooden shims to level the hotplate to insure a level bullet tin.

When the bullets are completely lubed and have soaked in the heated lube, simply unplug the hotplate and let the “bullet-pie” cool. I don’t like to set the tin in a refrigerator to speed this process up, as the lube will contract away from the bullets if cooled too fast. Let them cool at room temperature.

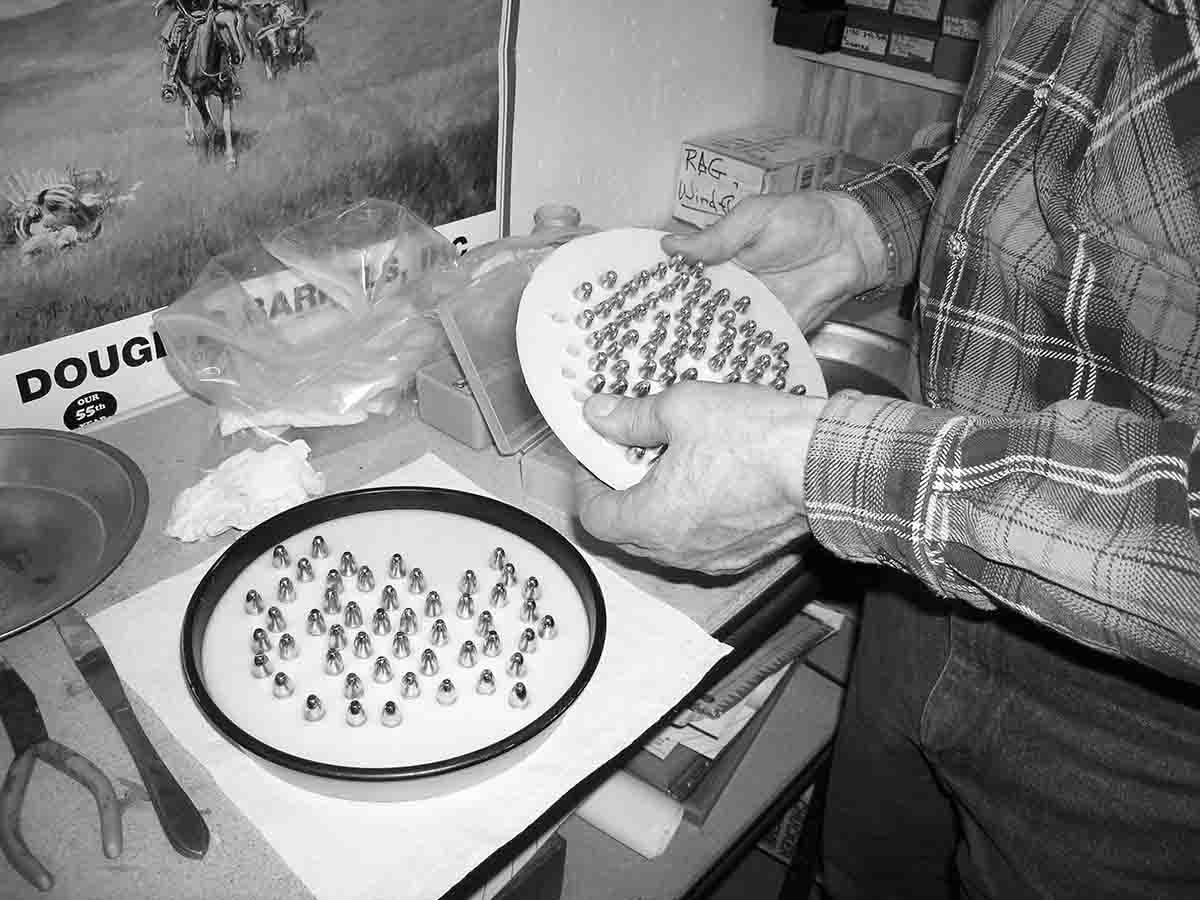

When the lube has solidified, simply turn the tin over and catch the cake of lube containing the bullets. The bullets can be easily pushed out of the lube cake, point first. If you let the lubricant cool overnight, be prepared for a harder job of pushing the bullets out. I use an old leather glove on my hand to push out the bullets as the spitzer nose on many bullet designs can lead to a sore thumb.

At this point you have a batch of cleanly lubed bullets with full grease grooves. Once you wipe the bases clean they are ready to use. I store my lubed bullets in airtight containers and have shot them as much as a year after lubing with no adverse results. I also cover the “lube pie” when I’m done to keep out dust and dirt as well as keep the lube fresh. As long as a double-boiler is used to melt the lubricant it can be re-melted over and over. If you happen to run the water-tin out of water and scorch the lube…throw the lube out, it will only cause you headaches.

Pan lubing is an effective way to lubricate large batches of bullets very uniformly and without deformation. Harry Pope claimed that the best way to shoot a cast bullet was just the way it came out of the mould; no sizing. Of course, that means that you start with a good bullet of the correct size, but I believe old Harry was right. Pan lubing is an easy way to save a few dollars on the equipment needed to reload your own black powder ammunition and the only way to efficiently lubricate tapered bullet designs.