Product Reviews

Montana Vintage Arms Muzzleloader Sight, BACO’s Swaged Bullets for Paper Patching, SPG Sales “Bear Grease” Patch and Bullet Lube

column By: Steve Garbe / Mike Nesbitt | June, 23

Montana Vintage Arms Muzzleloader Sight

Many of us who shoot muzzleloaders, especially roundball muzzleloaders, have wanted a quality tang sight that was adjustable for windage and elevation, but more importantly, that could be adjusted for the angle of the staff so that it was straight vertically. As many muzzleloaders vary in wrist angle, most sights on the market could not be plumbed without being altered. Even then, some sights were simply not suitable. Also, what was desired was a simple sight with a short staff that would not get in the way when used in the field or when folded down against the wrist.

The new MVA “Muzzleloader Sporting Sight” is exactly that – a simple, adjustable tang sight that does all one needs and nothing more.

I mounted the MVA sight on a favorite .40 caplock Ohio rifle to test function and suitability. I estimated that it would provide for roughly 300 yards of elevation with roundball loads. The pitch of the staff was easily adjusted to give a straight vertical alignment and the windage adjustment allowed me to regulate the rear sight to the front sight for zero windage. The simple scale on the staff allows for repeat sight settings for different yardages, very important with a roundball rifle.

If you are looking for a high-quality, traditionally styled peep sight for your favorite hunting rifle, whether it is a muzzleloader or breechloader, look no further that the “Muzzleloader Sporting Sight” from Montana Vintage Arms. The price is $195. Contact Montana Vintage Arms in Belgrade, Montana, at 406-388-4027. MVA has many other great sights, scopes and accessories on its website (montanavintagearms.com) and the MVA high-quality product line is made right here in the U.S.

BACO’s Swaged Bullets for Paper Patching

The shooter will have to decide if those .442 diameter bullets are on the large size for the .44s or perhaps on the small size for the .45s. Each barrel can have a preference and it’s nice to have such a variety to choose from in order to find what our rifles really like.

One bullet is offered with a diameter of .459, weighing 480 grains. If you have a .45-caliber rifle with a larger than average bore, that might be the best choice.

From there, the bullet diameters jump to .492 and those are for the .50s. The weights for those begin at 450 grains (just right for the 50-70) and climb to 650 grains to be suitable for today’s faster twist .50-caliber barrels; those bullets are followed by ones with a .504 diameter that have weights beginning at 350 grains and climbing up to 650 grains.

The list of diameters is completed with some bullets swaged for the .577 rifles, with diameters of .570 at 450 and 480 grains plus diameters of .578 with bullets weighing 450, 500, 550 and 600 grains. That’s quite a lineup and when I made my notes about this selection, most of them were in stock and ready to be shipped.

What brought these swaged bullets for paper patching to my attention, was I wanted some 400-grain bullets of .438 diameter to try in my 44-77. This was following my “dissecting” of the old original UMC 44-77 cartridge, which contained a .438 diameter paper-patched bullet of 405 grains. Trying some of the BACO swaged bullets might be a good step to take before buying a bullet mould.

The final loading, which gave me closer to the wanted results, held 75 grains of the Swiss 1½ Fg powder, an over-powder wad, 1⁄8-inch of BPC Lube, an over-lube wad, then the patched bullet. Ignition was provided with Federal No. 150 Large Pistol primers. This load, when fired out of “Hefty Hannah,” gave me meat-making accuracy at 100 yards, which is what I really wanted. More shooting will be done, of course, and my heavy 44-77 might be used in our Paper Patch Match as well, using the swaged bullets from Buffalo Arms Company.

The 400-grain bullets I used are priced at $28.99 for a box of 50, and the price per box goes down when the size of the order is increased. Heavier bullets are somewhat costlier. Trying the bullet weight and diameter with these swaged bullets is a great way to determine whether a bullet mould for similar-styled bullets should be purchased. Contact Buffalo Arms in Ponderay, Idaho, at 208-263-6953, or via the website at buffaloarms.com. There are many great black-powder shooting supplies available and good quantities are in stock.

SPG Sales “Bear Grease” Patch and Bullet Lube

We specifically tried the new lube at temperatures of around 30 degrees Fahrenheit, as it is our opinion that getting a lube to work in colder, dry conditions is the toughest order of all. For many of us, this temperature represents typical fall hunting conditions.

The rifle has a .45 barrel with a 1:66 twist and the load was 70 grains of Swiss 3fg, .446 lead roundball, a .015 linen patch on the ball and a .010 over-powder patch. I like to use the over-powder patch, as I think it really helps prevent gas burn-through, especially when using full-house loads.

We shot from benchrest at 60 yards, a typical turkey match distance. No wiping was done between shots. What was most noticeable about the Bear Grease was the fouler was in the middle of the three-shot group, and generally, the first three shots out of a roundball gun are typically the hardest to get to group accurately, as many rifles need to be “fouled-in” with a few shots before they settle down. The Bear Grease seemed to eliminate that procedure in this rifle.

Given these results, I’m planning on using the Bear Grease for more extended match shooting and will provide updates on the results.

I was curious as to how the Bear Grease would work in relubing 22 rimfire ammunition. This is something I’ve done with regular SPG Lube for a number of years with older ammunition that I believed the original lubricant had dried out on. To be honest, I have to say that some rifles liked the “relubed” ammunition and some showed no change at all in accuracy. I have noticed that some rimfire rifles, which have a propensity towards leading or carbon build-up have been cured by the relubing process.

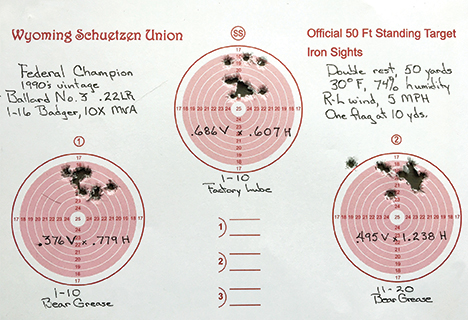

The small tin that the SPG Bear Grease came in made it easy to put just a thin film of lubricant on the bullet by simply rolling it across the lube. I fired a couple of foulers, in a clean, dry barrel and then two, 10-shot groups at 50 yards with greased ammunition to do an initial test, and followed those up with a 10-shot group fired with the ammunition as it came from the factory. I cleaned the barrel and borescoped it after the 22 rounds of Bear Grease ammunition and after the 10-round group of dry factory ammunition.

The groups in the photo show more horizontal spread than vertical due to the 5-mph wind. Accuracy was slightly better with the Bear Grease ammunition, but the real eye-opener divulged itself when I cleaned the rifle. There was noticeably less hard fouling and carbon build-up in the leade when using the greased ammunition; two patches would clean the barrel easily, whereas the factory-lubed ammunition required four patches to completely swamp out the fouling. I noticed a slight amount of leading with the factory ammunition and none at all with the Bear Greased cartridges.

Given these test targets, I will be using SPG Bear Grease in my roundball guns, as well as in most of my rimfire rifles, especially when using old ammunition. SPG Bear Grease comes in a handy 2-ounce tin for the price of $8 or an 8-ounce block for $18. To place an order contact SPG Sales in Kirksville, Missouri, at 660-988-4099, or look them up at blackpowderspg.com. Be sure to look through their website as it features their other great products for shooters, by shooters.