Product Reviews

SPG Tropical Lube and BACO Bore Wipes in the 40-65 Black Powder Cartridge Rifle

column By: Zack Taylor / Mike Nesbitt | December, 23

SPG Tropical Lube and BACO Bore Wipes

in the 40-65 Black Powder Cartridge Rifle

Some time ago, I heard that Larry Baker at SPG Sales, had developed a bullet lube to be used in warmer climates that would stay on the bullet at 145 degrees Fahrenheit. I live and shoot in southern Arizona in the heart of the Sonoran Desert and felt shooting here would be a good test of this new lube. The new lube is dubbed “SPG Tropical.” I had already been using the Buffalo Arms Company Bore Wipes in our .44 and .45 caliber rifles but just used patches in the .40 caliber rifles. I decided to try both the SPG Tropical and the .40 Caliber BACO Bore wipes together for an entire shooting season (in a known accurate rifle) to evaluate that combination for competitive midrange target and BPCR silhouette competition.

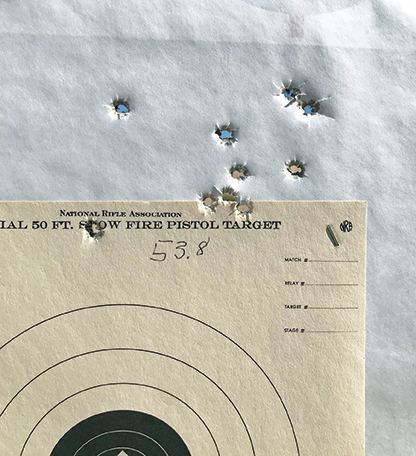

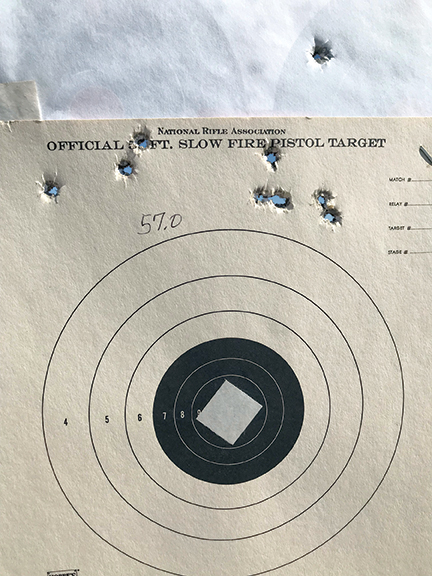

The target was suggesting that the rifle preferred two loads over the others. Using fire-formed and lightly annealed Remington brass and Swiss 1½Fg powder, the loads were 53.8 grains with the Federal 150M primer and 57 grains with the CCI-300 primer, both with the same lot of Swiss 1½Fg powder. The ram swinger indicated that the 57-grain load held vertical much better than could be expected. This is the load that went to Raton, New Mexico, on July 14-15, 2023.

Using this method, I could fire 72 or more shots without cleaning the barrel. The bore was clear and clean at the end of the match even with ambient temperatures varying between 42- to 115-degrees Fahrenheit on any given day; I enjoyed match-winning accuracy throughout. On July 15, 2023, the last day and last relay (turkeys) at Raton, I hit 14 of 15 turkeys as rain clouds came in and sight corrections were made for most of the 15 record shots. Yes, I think I will go with this combination again; SPG Tropical seems to be a great lube for our hotter temperatures.

– Zack Taylor

RCBS’s Partner Press

More recently, some maintenance for this press became necessary because, unnoticed by me, the handle had come loose. This must have happened many years ago because the press was still used with the loose handle. What that caused was some distortion on the threads of the handle rod, as well as in the press where the handle attaches, which ultimately wore on the threads until the handle couldn’t be re-tightened.

Consequently, an e-mail was sent to RCBS explaining that I needed a new handle rod for my Partner Press. To my surprise, a new rod was delivered to my home, without charge, even before I got a reply to my e-mail note! The new handle rod and my old press were taken to Allen Cunniff’s shop, where the threads in the press were cleaned up and then the new handle rod was installed – nice and tight. I was back in business.

The Partner Press is not the largest reloading press, but it easily handles everything I need it for. It is considered a small “O-frame” press, die-cast of aluminum which makes it light and portable. It has a “window” of four inches with an operating stroke of 3½ inches, which simply means that some of my longer Sharps cartridge cases, such as the 44-90 with its 25⁄8-inch cases or the 45-110 with the 27⁄8-inch brass, must be entered at a slight angle to get the bullet and case aligned in the seating die before bullets can be seated.

With a manufacturer’s suggested retail price of just a penny less than $210, the Partner Press is said to be “the most affordable press in the RCBS line.” While that’s fairly reasonable, you can quickly find more inviting prices by simply shopping around. After using mine for nearly 40 years, I plan on using it for many years to come, especially with the outstanding support of RCBS’s customer service.

– Mike Nesbitt