The “Case” for the 40-60 Maynard

feature By: Steve Garbe - Photos by Sheryll Garbe | June, 24

My first shooting in BPCR Silhouette was done with a 11-pound 45-70 Shiloh 1874 and it worked well, but the recoil with 500-grain bullets could get to be tiring, especially since the National Championship, at that time, consisted of 120 shots for score over three days. Add in the sighters and the recoil became a real issue. I wanted to use a cartridge with less recoil as I thought it would help with the overall score. At the time, my preference was a straight case over a bottleneck because that was the type case I was used to reloading for.

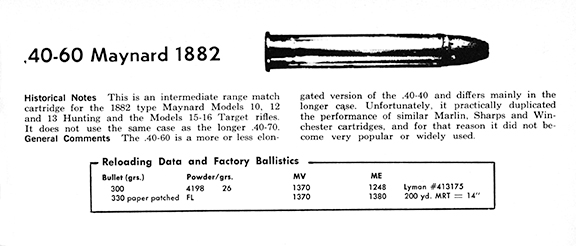

The 40-60 Maynard 1882 does not have the wide rim that many shooters associate with the Model 1873 Maynard rifles. Barnes lists the case dimensions as follows: case length of 2.2 inches, a rim measuring .533 and base diameter of .454. Factory specs showed a .417 diameter bullet and a factory twist of 18-20 inches. I intended to use .409 diameter cast bullets in my .408, 1-18 twist Douglas barrel.

This paragraph is from the NRA Silhouette Rule Book:

(d) Cartridges will be of the American black powder era, originally black powder loaded, manufactured prior to 1896, and originally chambered in American-manufactured rifles, taking into account normal variations in types of brass and primers, as well as bore sizes, rifling styles, twist and chamber dimensions. Limited use and special chambering (wildcats) are not acceptable. Cartridges must be loaded with black powder or any BATFE approved black powder substitute only. No smokeless powder in any quantity may be used. Match officials, at their discretion, may select one or more loaded cartridges at random, pull bullet, and check contents.

Before I began using the 40-60 Maynard for local BPCR silhouette competition in 1989, I consulted with several members of the Silhouette Committee and asked their opinion of the 40-60 Maynard cartridge with normal allowances made for modern barrels and bullet diameters. I was assured that the changes were within reason and would not be a problem. However, at the 1990 National BPCR Silhouette Championship, where I first used the 40-60 Maynard, I made a point to have the rifle and cartridge “juried” so there would be no misunderstanding. Since then, the 40-60 Maynard has become a fairly common silhouette round, preferred by some black powder riflemen, myself included.

Currently, excellent 40-60 Maynard brass can be purchased from Buffalo Arms Company. BACO re-draws 30-40 Krag or 303 British cases out to the proper 2.2-inch length and I think this is much better plan than fire-forming, as the drawing process seems to uniform the neck thickness. Rocky Mountain Cartridge, LLC. also produces turned 40-60 Maynard brass that have the added option of being cut for either Large Rifle or Small Rifle primers. One early problem with forming cases was the rim thickness of 30-40 Krag brass varied quite a bit. To solve this, when chambering the rifle (with a reamer from Pacific Tool and Gauge), I did a minimum rim depth cut that corresponded with the thinnest rims and then cut all the rims to this depth on a lathe. Some cases would have the caliber stamping completely removed from the rim while others were just barely touched. I also uniformed primer pockets after thinning the rims as they showed significant variation as well. Flash holes were also uniformed to .096 and de-burred. The 40-60 reamer that I used had a long 1½-degree leade that allowed me to seat bullets out at least one driving band.

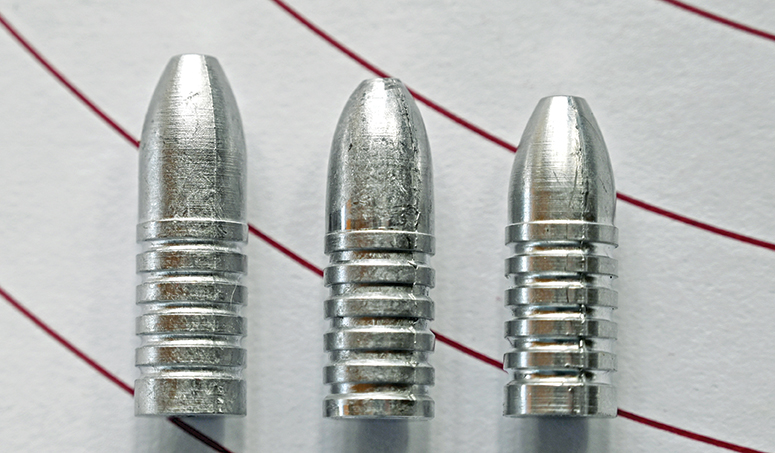

Powder capacity with the 40-60 Maynard is very similar to the 40-65 WCF, depending largely upon bullet design. With the 385-grain Tom Ballard bullet used in the sample load, I was able to drop-tube in 59 grains (weight) of 1½Fg Swiss powder and seat a .060 Walters Poly Wad with .150 compression. Using a thinner wad and .075 compression would allow the use up to 65 grains of powder. Chronograph readings with the 385-grain, 1-10 alloy bullet and 59 grains of 1½Fg were 1269 fps average (ten shots) with an extreme spread of nine feet per second. Extreme Spread has always been the number I am most concerned with when doing load development, especially when that load will be used beyond 300 yards. Here is the sample load tested:

385-grain .40 Ballard bullet (.400/.409, 1.248 length), 1-10 alloy, sized to .409, SPG Lube, .060 Walters Poly Wad, 59 grains (weight) Swiss 1½Fg, .125 compression, Remington 2½ Large Pistol primer, BACO cases neck sized and expanded to .406, light taper-crimp, overall cartridge length 2.957.

Using 61 grains of Swiss 1½Fg and slightly more compression increased velocity to 1287 fps. Switching the 59 grains of Swiss 1½Fg for 3Fg resulted in a velocity of 1349 fps. Accuracy for all three loads at 200 yards ran nearly identical at 2¾ to 3 inches for 10-shot groups.

The rifle used for testing was a Single Shot Inc. High Wall fit with a 1-18 twist Douglas barrel, 30 inches long. The barrel was not cleaned between shots, but a blow-tube was used. The 18-inch twist just stabilized the 385-grain Ballard bullet with no serious tipping, however, I think a 16-inch twist is a better choice for any .40 caliber rifle that will be used with heavy-for-caliber bullets over 1.25 long. Twists as tight as 12 inches have been experimented with, but they seem to magnify casting flaws, with resulting fliers. A 16 to 15-inch twist (or possibly a 1-14) would represent the best all-around choice for mid-range shooting out to 600 yards. I currently have a new .40-60 Maynard rifle in the works and it has a 1-14.5 twist Bartlein barrel that should easily handle bullet lengths to 1.5 long. The Greenhill Formula gives a minimum twist of 16.6 for a .408, 1.5-inch bullet, but I have had the best luck by tightening the Greenhill results by 2 inches for bullet velocities in the 1100 to 1300 fps range.

By the way, sharp-eyed readers will notice the Montana Vintage Arms Model “A” scope on the rifle equipped with what appears to be newly manufactured Unertl mounts. These scope mounts are indeed a new product from MVA and performed flawlessly during the shooting for this article. The “A” 10X scope and MVA Unertl mounts made a great combination for load testing; being very repeatable and precise in adjustment. This MVA scope and mount combination is going to get a good workout for both Silhouette and target shooting in the months to come.

Large Pistol primers turned in the lowest ES readings with straight black powder loads, as was expected. When using Large Pistol primers, one must be sure that the breechblock is correctly hardened as cupping around the firing pin hole can result if the breech face is soft.

The 40-60 Maynard also makes for a very practical and efficient hunting cartridge as well. When loaded with Swiss powder and a typical 350-grain bullet, velocities are in the 1300-1350 fps range. I have killed a couple of deer, one antelope and one elk with the 40-60; within responsible hunting distances (under 200 yards) and using a soft alloy bullet, all animals fell to a single shot. Penetration with shoulder shots on the deer and antelope showed a complete pass-through. The bull elk had the bullet captured by the hide on the offside.

For those who like to also work up loads with smokeless powder, my favorite heavy .40 caliber bullet for the 40-60 Maynard is the old RCBS’ 400-grain CSA bullet. This bullet seats deep in the case and takes up much of the room so that fillers are not really necessary. I cast this bullet from No. 2 alloy, size it to .409 and with 22 grains of 4198 it will turn in velocities around 1340 fps with very good accuracy.

The 40-60 Maynard is to my mind one of the most useful of .40 caliber straight cases and has many applications for black-powder Schuetzen, BPCR Silhouette and Mid-Range BPTR matches, as well as being an efficient hunting caliber with smokeless or black. Case forming is easy, brass is relatively cheap and the cartridge itself very well balanced. For the rifleman who prefers a straight rather than tapered or bottleneck cartridge case, the 40-60 Maynard is an intelligent choice.

Component Sources:

Douglas Barrels

5504 Big Tyler Road

Charleston, WV 25313-1398

Ph: 304-776-1341

Buffalo Arms

660 Vermeer Court

Ponderay, ID 83852

Ph: 208-263-6953

Bartlein Barrels, Inc.

W208N16939 N. Center St.,

Jackson, WI 53037

Ph: 262-677-1717

Pacific Tool and Gauge

675 Antelope Rd.,

White City, OR 97503

Ph: 541-826-5808

Rocky Mountain Cartridge, LLC.

1195 Lane 10

Worland, WY 82401-9704

Ph: 307-347-4547