Black Powder Cartridge Neck Tension Follow Up

feature By: Rick Moritz | April, 24

INTRODUCTION

For clarity, I should share what terms I use when describing neck tension. First, there is “interference fit”. We have a cartridge case neck smaller than the bullet diameter, which requires force to seat the bullet into the case. Once the bullet is seated, the cartridge case and bullet act as one unit. The bullet cannot be pulled from the case with the fingers, and it is unlikely that the bullet will spin. Secondly, there is a “clearance fit”. The inside diameter of the cartridge case neck is equal to or larger than the bullet. There is no force required to seat the bullet outside of a bit of finger pressure. The cartridge case and the bullet can move relative to each other and do not act as one unit. One can usually remove the bullet from the cartridge case by pulling it out with one’s fingers. Some reloaders describe the clearance fit as “slip fit” since the bullet slips in and out of the case.

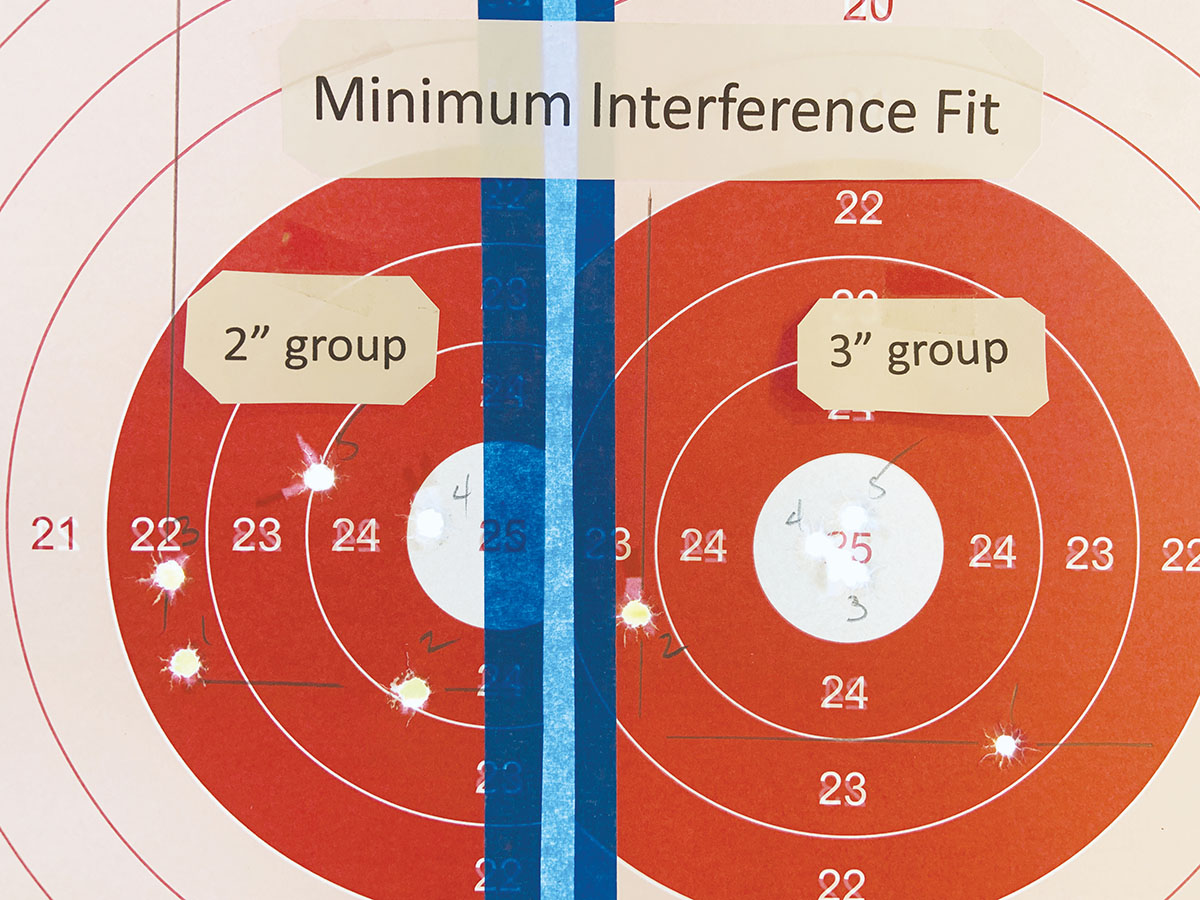

Meticulously, I selected three specific neck tensions for the current experiment: a minimum interference fit, a sized slip fit, and an as-fired slip fit. These choices were not arbitrary; instead, they were made to ensure a comprehensive understanding of the impact of different neck tensions on accuracy. By selecting these specific tensions, I aimed to eliminate any potential ambiguity in the results, providing a clear and precise analysis of the effects of neck tension on accuracy.

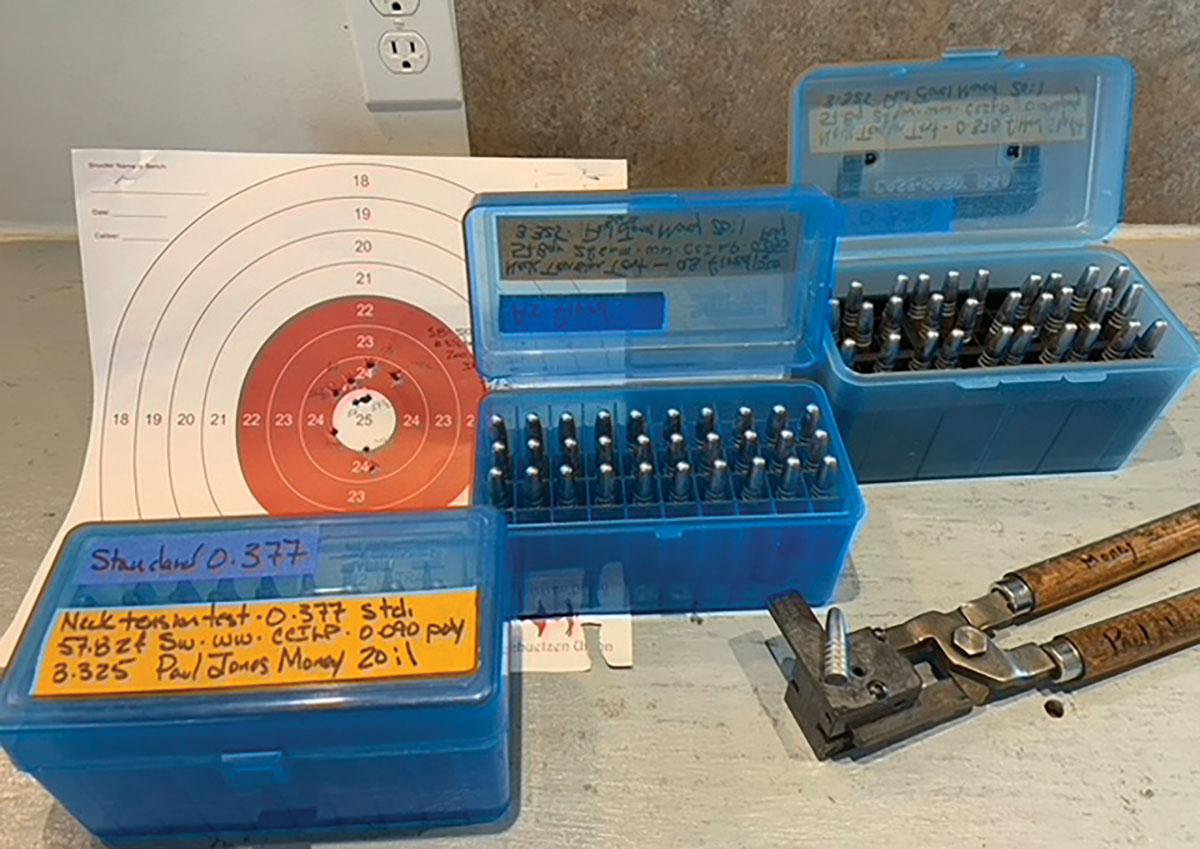

My method for my match ammo involves a minimum interference fit. This is achieved using an expander of 0.377 inches, a modified gage pin, resulting in an inside case neck diameter of 0.376 for a 0.376 bullet. My gage pins limit me to 0.001 increments; all the expanded cases accept 0.375 gage pins, and most accept a 0.376 gage pin. This results in a 0.001 neck tension. There is a slight variation in the final inside diameter due to the variation in the brass neck thickness and, perhaps, brass hardness.

The sized slip fit cartridge cases were generated by sizing clean, annealed cases, which were expanded with a 0.378 expander, resulting in a neck inside diameter of 0.377, creating a clearance fit of 0.001. These cases were not belled since the expansion is just enough to allow the bullet to enter the case with light finger pressure and minimal run-out. I know of two national champion BPCR shooters who have used this method. When questioned, they called it a “sized slip fit” since it required sizing and expanding to get just enough clearance for the bullet. Obtaining the detailed information was difficult, but I endeavored to persevere. They also used fairly high velocities, greater than 1,300 fps.

Some BPCR reloaders prefer to reload un-sized cases as fired, resulting in an as-fired slip fit. These are the same for our purposes: fired cases are cleaned with no sizing, and the cases are primed and filled with an appropriate amount of powder, a wad and then compressed. The bullet is then easily slid into the case. There is no neck tension; my fired cases would accept a 0.378-gauge pin and sometimes a 0.379 pin. This is .002 to 0.003 of clearance between the case neck and the bullet. I will reference these as “fired slip fit”.

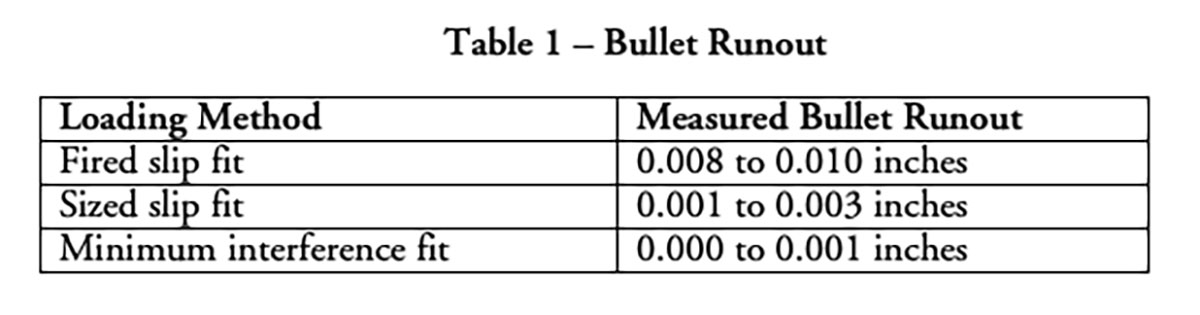

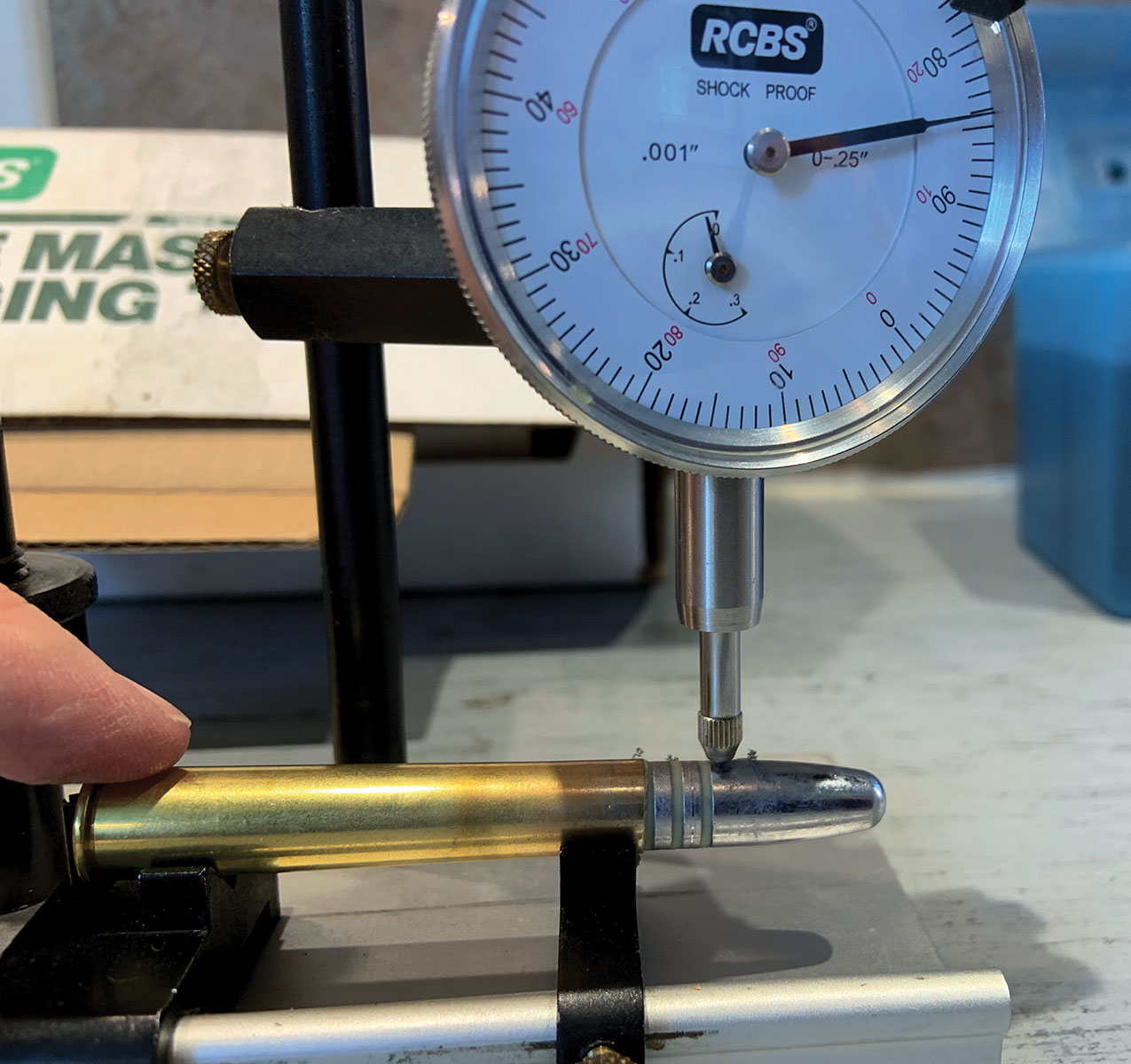

As part of the loading process, I measured the bullet run-out for the three loading methods. The results are in Table 1.

It should be kept in mind that when measuring bullet run-out, we are not just measuring bullet alignment with the case. We are also measuring variations in cartridge neck thickness, the cylindricity of that portion of the bullet within the cartridge neck, and the mechanical accuracy of our dies used in sizing and seating. Proper brass cleaning, quality dies, and lathe-turned bullet moulds can help achieve high-quality “straight” match ammo.

TESTING METHODOLOGY

ANALYSIS

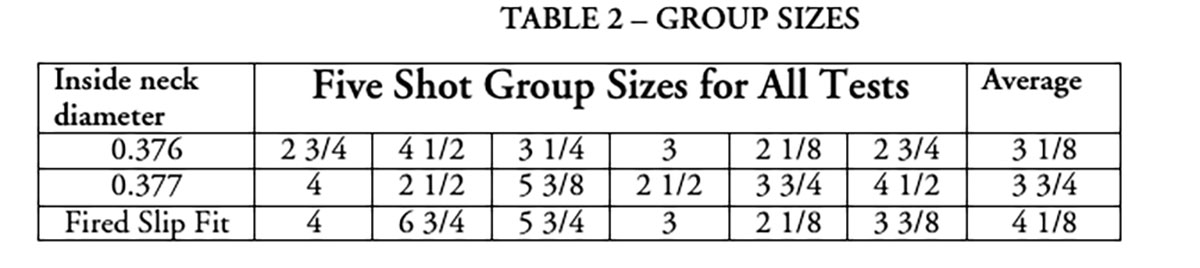

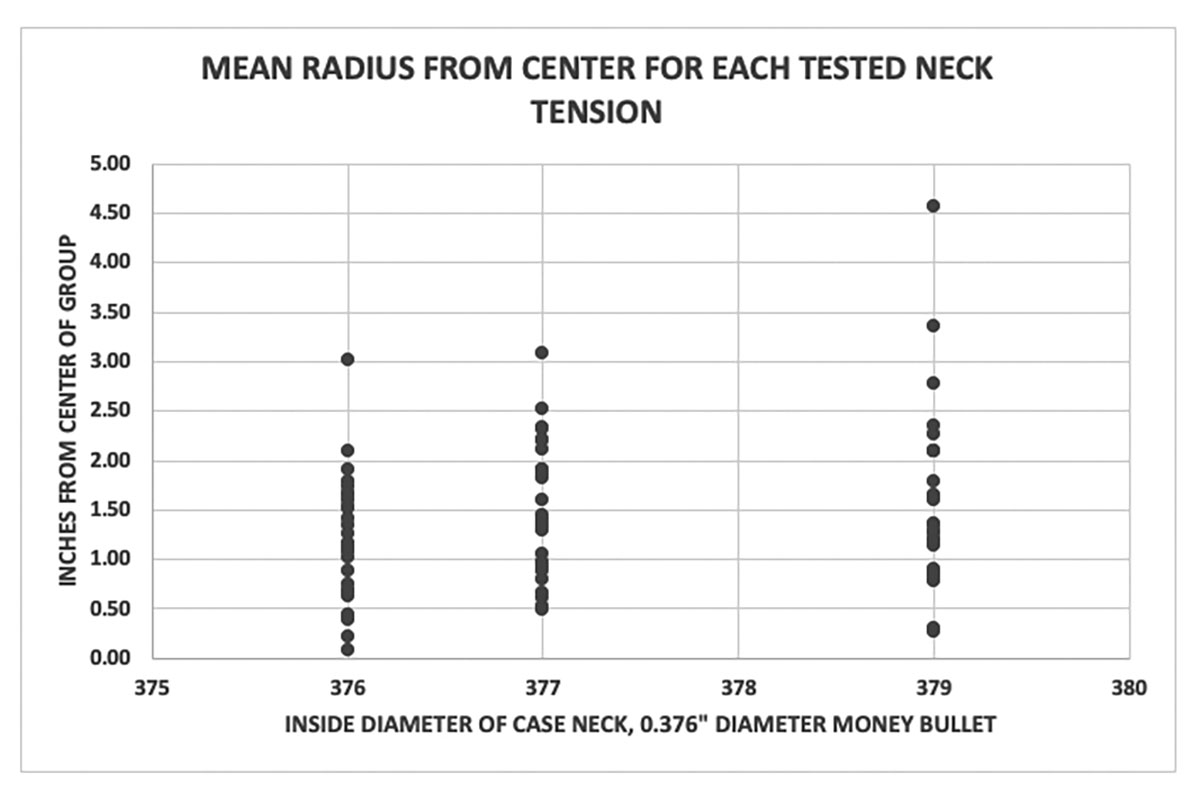

The average group sizes are presented in Table 2, and it can be seen that the inside neck diameter of 0.376 and minimal interference fit indicate the best results. Since group sizes are based on the two widest shots, I do not feel they give the best information.

A careful review of Graph 1 shows that out of 30 shots for each of the three tests, two shots were two inches or more from the group center for the minimum interference fit, seven shots were two inches or more from the group center, and the fired slip fit resulted in eight shots that were two inches or more from the group center. Again, all shots may not be seen on the graph as some are the same distance from the center and will plot on top of each other.

As shooters we can read and adjust for the wind. We cannot adjust for random vertical dispersion. I constantly review my data to determine if any test might exhibit more vertical dispersion than another. A one-way ANOVA table can analyze three or more tests for vertical dispersion. This was completed, and I can confidently state with 92.5 percent confidence that the minimum interference fit has less vertical dispersion than the other tested methods. This does not rise to the gold standard of 95 percent confidence, so the reader must draw his conclusions. The sample groups presented for the minimum interference fit, sized slip fit, and as-fired slip fit indicated the rounder groups from the minimum interference fit. In contrast, the sized slip fit has some vertical. Contrast these with the as fired slip fit; the vertical tendency is apparent.

CONCLUSIONS

I do not plan on doing any more neck tension tests anytime soon. After coming full circle, I will stick with an inside case diameter of 0.376 inch for a 0.376-inch bullet. As an item of interest, my 45-90 Creedmoor rifle uses a 0.459-inch Paul Jones bullet. I have found that a 0.460-inch expander, which expands the case to 0.459 inch, gives the best results. S