Product Reviews

SPG Gun Wax, Montana Vintage Arms – New Products 2024, Lyman’s “Short .45” Black Powder Taper Crimp Die

column By: Steve Garbe (Photos by Sheryll Garbe), and Mike Nesbitt | April, 24

SPG Gun Wax

Steve Garbe - Photos by Sheryll Garbe

The old military oil-finished Springfield after a rubdown with SPG Gun Wax.

SPG Wax enhanced the fine finish on this D. King flintlock.

This SPG Gun Wax will go into my range kit, as well as the workbench for revitalizing and maintaining gunstock finishes. We tend to think that once a stock is finished that we don’t need to tend to it, but to keep them looking their best and also being somewhat weatherproof, a rubdown with SPG Gun Wax is a smart maintenance regimen.

For contact information: SPG Sales, P.O. Box 745, Kirksville, MO 63501. Phone: 660-988-4099 or blackpowderspg.com. Their website is full of quality products for the black powder shooter – you won’t be disappointed.

Montana Vintage Arms – New Products 2024

Short Hood Front Sight, “Stepped” Rear Scope Block

& Windage Adjustable Scope Block

Steve Garbe - Photos by Sheryll Garbe

The new Step Block rear scope block from MVA.

Short Hood Front Sight: The first new product is a globe front sight specifically designed to appeal to hunters who like an interchangeable insert front sight but have found most to be too dark for use in the field during poor light conditions.

The new MVA Short Hood Insert Front sight.

My preference has always been for an insert front sight because I like to tailor the insert to the hunting conditions and game. A crosswire works great in good light and for small varmints, especially when holding over for windage and elevation at extended ranges. For general purposes, it is hard to beat a square-topped post of medium width, and of course, many hunters like a bead front sight. With the new MVA sight, you can use all of the above. The Short Hood sight takes all standard MVA inserts and also features the same dovetail locking screw in the base. The price is $115.00 and the sight comes with an insert card.

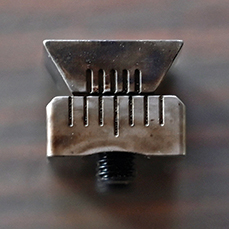

Stepped Rear Scope Block: The second new product is a “stepped” rear scope block that fits all MVA scopes and many of the old Lyman and Unertl scopes as well. One problem that many scope shooters have with their telescopic sights is not enough elevation to reach the longer ranges. With the new Stepped Block, one can simply slide the rear mount to the higher block to give additional elevation, rather than make a complete block change. The main block is .400 high and the step provides for an additional .250 elevation that will easily allow adjustment to the ram line and quite a way beyond.

Doing the math, an additional .250 height of elevation should provide for an additional 125 minutes of elevation when using a 7.2-inch scope block spacing. Having the Step Block on your rifle is just a good way to cover every sight adjustment you may need, without changing blocks and introducing more variables to your sight settings. The MVA Step Block goes for $40 and is ready for immediate delivery.

Windage Adjustable Scope Block: The third new product, which will really interest those of us who regularly shoot old vintage rifles, is a windage adjustable scope block that allows one to adjust the scope mounts to a zero windage setting on both the blocks and the mount.

The MVA Windage Scope Block.

For more information on these great new products contact: Montana Vintage Arms, 61 Andrea Drive, Belgrade, MT 59714. Phone: 406-388-4027 or visit their website at montanavintagearms.com. All of their products come with MVA’s excellent customer service and outstanding warranty. These new products are in stock and ready for immediate delivery and just in time for the 2024 shooting season.

Lyman’s “Short .45” Black Powder Taper Crimp Die

Mike Nesbitt

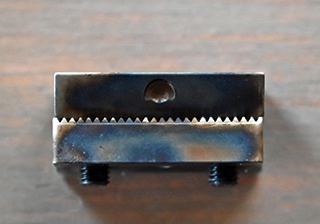

Lyman’s “Short .45” Taper Crimp die.

The die is shown with both 45-70 and 45-90 loads, plus the .300-inch high collar.

In use, this taper crimp die by Lyman works just fine and it is exactly what I wanted. At first, I was a little worried that the hole in the top of the die was not big enough because it would not allow the nose of the bullet to enter. I wondered if this die had internal dimensions that were meant for deeply seated bullets, such as what would be used through repeating rifles. That, however, is not a problem and, so far, I have not found a bullet that extends beyond the mouth of the case too far for this die, paper patched or otherwise.

Close-up of the 45-90 load and the taper crimp is barely visible.

This taper crimp die is now a regular member of my 45-70 and 45-90 reloading dies and I’m using it with both grease groove and paper patched bullets. It puts a “hold” on the paper patched bullets firm enough that the cartridges can be carried in a cartridge belt without the fear of losing the bullets. I also believe, I’ll see an improvement in accuracy because the bullets are not being squeezed down like they are when the file trim die is used for “crimping.” Lyman’s current suggested retail price for one of these dies is $33.95 and that seems like a bargain when compared to similar dies by other makers. Contact information for Lyman Products and Buffalo Arms Co., is: LymanProducts.com or phone: 800-225-9626 and BuffaloArms.com or phone: 208-263-6953.